ADD:

Chumen Town,Yuhuan CIty,Zhejiang Province, China

TEL:

E-MAIL:

PRODUCT LIST

PRODUCTS

DIN 2PC FLANGE BALL VALVE

2PC Stainless Steel DIN F4/F5 Flanged Floating Ball Valve

-

RST Valve company is a industry valves manufacturer, including Thread & Flange Ball Valves, Gate Valves, Globe Valves,

Check Valves, Y Strainers in stainless steel, carbon steel, cast steel, forged steel and alloy steel. -

Flanged Ball Valve includes 1PC Stainless Steel Flange Ball Valve, 1PC Carbon Steel Flanged Ball Valve, 1PC API/DIN

Flanged Ball Valve, 2PC API Flanged Stainless Steel Ball Valve, Two Piece DIN F4/F5 Flanged Ball Valve, 2 Piece JIS 10K

Full Port Flanged Ball Valve, 2PC Floating Flanged Ball Valve with ISO5211 Direct Mounting Pad, 2PC CF8M/WCB Flanged

Ball Valve, 3PC API/DIN standard Flanged Ball Valve, 3PC Stainless Steel Floating Flanged Ball Valve, Three Piece CF8M

150LB Flanged Ball Valve, 3 Piece Full Port PN16/40 Flanged Ball Valve. -

RST VALVE is one of the professional Ball Valve Manufacturer in china. We supplies: floating ball valve,trunnion ball valve,metal seated ball valve,threaded end ball valve,butt welded ball valve,Forged steel ball valve etc, We can manufacture and

supply ball valve according to your requirements Main material of the products are A105, WCB, C5,WC6, WC9,CF8, CF8M,

316 and so on. Tops Valve design by the standards of API6D, ASME, ANSI, JIS, DIN, BS, GB, etc. -

DIN 2PC Flange Ball Valve provides a high quality yet economical two piece flanged full-bore ball valve solution in DIN PN16 and PN40. Designed for safety, long life and easy maintenance, this valve assembly features rugged construction, full-bore

uninterrupted flow path, and blow-out proof stem and packing. Ideal for operation in harsh environments such as chemical

processing, petrochemical, oil and gas production, pulp and paper and more.

|

Product Name |

2 Piece DIN Floating Full Port Stainless Steel Flanged Ball Valve |

|

1. Material |

SS304/316/304L/316L ( CF8/CF8M/CF3/CF3M), WCB, etc. |

|

2. Size |

1/2~8 inch ( DN15~DN200) |

|

3. Thread standard |

ISO9001 & CE, TS |

|

4. Port |

Full Port |

|

5. Working Pressure |

PN16/40/64 |

|

6. Connection Ends |

Flange |

|

7. Working Temp. |

-20~300℃, or according to customer requirements for different industry. |

|

8. Suitable Medium |

Water, Natural Gas, Oil and some corrosive liquid |

|

9. Operated |

Handle operated, Locking device is option |

|

10. Inspection & Testing |

According to API598 |

|

Shipment |

|

|

Delivery Time |

15~20 Days |

|

Package |

Standard Exporting Plywood Case |

|

Shipping Port |

Ningbo/Shanghai, China |

|

Shipping Terms |

Exw, FOB, CFR, CIF, etc. |

|

Payment Terms |

T/T, Western Union, PayPal, etc. |

|

|

30% prepayment, 70% balance paid before shipping or against copy of BL |

|

Country of Origin |

Wenzhou city, China |

|

Production Capacity |

6000 ton/year |

|

MOQ |

10 PCS/size |

Specifications:

1. Construction

All valve bodies feature a sturdy two-piece construction and machined mounting pad conforming to ISO 5211 for easy automation; direct mounting of pneumatic or electric actuators, limit switches, and handle extensions.

2. Seats

Resilient slotted seats are designed for bubble-tight shutoff at high and low pressures, reduced friction for less wear; minimum seat damage, and lower operating torque. Seats are furnished in TFM, Virgin PTFE, or glass filled PTFE as standard. Additional

materials are available in Ball Valves Seat Variations’ Bulletin T-624.

3. Stem

The high performance valve stem assembly offers blow-out proof safety features plus long service life. The stem is guided by the

valve body and an adjustable packing gland fitted with live loaded spring washers that compensate for surges in pressure and

temperature. RST stem and packing design assures smooth operation, minimized operating torque and less wear.

4. Ball

Mirror polished to a corrosion resistant, low torque finish to prevent ball seat wear, the solid ball is precision machined with a

pressure relief hole in the stem slot to equalize pressure in the body cavity for bubble-tight shutoff and long service life.

5. Body & Trim Materials

Standard valve body materials are 1.44081.4308 Stainless Steel and 1.0619 Carbon Steel. Standard trim material for ball and

stem is 316 Stainless Steel. For Carbon Steel valves DN65 and up, standard trim is 304 Stainless Steel.

6. Antistatic

An anti-static device is built into the valve stem, to ensure electrical continuity between valve ball, stem and body; eliminating the

possibility of static electrical charges creating sparks within the valve, especially when handling volatile media.

7. Valve Body Finish

Carbon Steel valve bodies are painted for optimum protection. Stainless Steel valves are provided with a natural finish. Valves

comply with the highest industry standards in body finishing processes and procedures.

8. Fire Safe Valves

RST fire-safe valves are designed and tested to the requirements of API 607 5th Edition and to ISO 10497-2004 specifications.

Valves for fire-safe application are identified by the prefix “AF”. Fire-safe certificates are available upon request.

9. Secondary Sealing

All fire-safe valves are fitted with flexible graphite body seals and graphite stem seals. Flexible graphite exhibits unsurpassed

sealing properties for high temperature, high pressure service. In the event of a fire, a secondary metallic machined ring makes

contact with the ball to prevent leakage and provide shutoff in conformance with the latest industry fire-safe requirements.

10. Valve Accessories

A locking device to secure valve position is standard. RST carries a range of valve control accessories to suit your needs including manual gear operators for large valves, declutchable gear operators for actuated valves, spring return handles for dependable

automatic opening and closing, limit switches for on-off indication and other products such as positioners, indicators,overrides and

regulators.

Technical Specification:

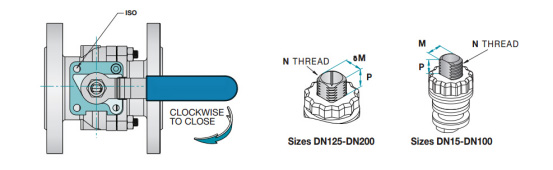

- Design & Manufacture standard: DIN3357

- Pressure & Temperature standard: DIN3230

- Face to face dimension standard: DIN3202

- Flange standard: DIN2543-2545/DIN 2501

- Test & Inspect standard: DIN2401.

Product Feature:

- Floating ball, full bore or reduce bore.

- ISO5211 mounting pad for option.

- Blow-out proof stem design.

- PTFE/RPTFE seat seal( Seat seal material could be decided by customer’s request or according to valve’s medium & temp. condition).

- Fire-proof and anti-static design if need.

- Operation: Hand wheel, Worm wheel, Pneumatic actuator & Electric Actuator.

Competitive Advantage:

- An ISO9001 ,CE certified manufacturer

- GOOD QUALITY

- RESONABLE PRICE

- ON-TIME DELIVERY

- STRICT EXAMINATION

- SINCERE SERVICE

- 18 MONTHS GUARANTEE

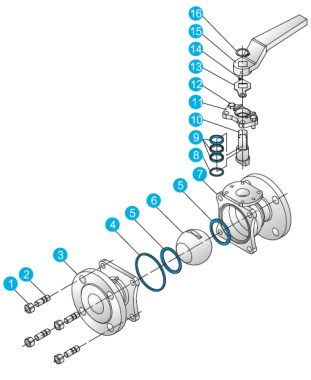

| Item No |

Part Name |

Material |

|

1 |

Nut |

SS304 |

|

2 |

Stud |

SS304 |

|

3 |

Cap |

CF8M/CF8/ WCB |

|

4 |

Body Gasket |

PTFE/RPTFE |

|

5 |

Seat |

PTFE/RPTFE |

|

6 |

Ball |

SS316/SS304 |

|

7 |

Body |

CF8M/CF8/ WCB |

|

8 |

Thrust Washer |

PTFE |

|

9 |

Stem Packing |

PTFE |

|

10 |

Stem |

SS316/SS304 |

|

11 |

Stop Cap |

SS304 |

|

12 |

Bolt |

SS304 |

|

13 |

Locking Pin |

SS304 |

|

14 |

Locking Nut |

SS304 |

|

15 |

Handle |

Plastic |

|

16 |

Stop Washer |

SS304 |

|

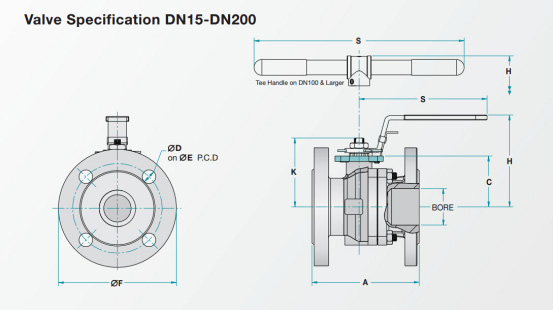

DN |

PN |

Port |

A |

C |

¢D |

¢E |

¢F |

H |

K |

M |

N |

P |

S |

ISO |

W(KG) |

|

15 |

40 |

15 |

115 |

36.5 |

14.0 x 4 |

65 |

95 |

86 |

57.5 |

6.3 |

3/8''-24UNF |

10 |

135 |

F04 |

2.3 |

|

20 |

40 |

20 |

120 |

40 |

14.0 x 4 |

75 |

105 |

90 |

61 |

6.3 |

3/8''-24UNF |

10 |

135 |

F04 |

3.2 |

|

25 |

40 |

25 |

125 |

45.5 |

14.0 x 4 |

85 |

115 |

96 |

69.5 |

9 |

9/16''-18UNF |

11 |

170 |

F05 |

4.1 |

|

32 |

40 |

32 |

130 |

50 |

18.0 x 4 |

100 |

140 |

102 |

74 |

9 |

9/16''-18UNF |

11 |

176 |

F05 |

5.5 |

|

40 |

40 |

38 |

140 |

62 |

18.0 x 4 |

110 |

150 |

114 |

89 |

9 |

5/8''18UNF |

16 |

200 |

F07 |

7.2 |

|

50 |

40 |

50 |

150 |

71 |

18.0 x 4 |

125 |

165 |

127 |

98 |

9.6 |

5/8''18UNF |

16 |

200 |

F07 |

9.7 |

|

65 |

16 |

63.5 |

170 |

89 |

18.0 x 4 |

145 |

185 |

146 |

131.8 |

16 |

7/8''-14UNF |

26 |

250 |

F10 |

14.8 |

|

40 |

107 |

18.0 x 8 |

164 |

149.8 |

|||||||||||

|

80 |

16 |

76 |

180 |

100 |

18.0 x 8 |

160 |

200 |

183 |

142.8 |

16 |

7/8''-14UNF |

26 |

250 |

F10 |

18.3 |

|

40 |

117 |

200 |

159.8 |

||||||||||||

|

100 |

16 |

100 |

190 |

121 |

18.0 x 8 |

180 |

220 |

214 |

170.5 |

18 |

1-1/8''-12UNF |

26 |

400 |

F10 |

29.5 |

|

40 |

134 |

22.0 x 8 |

190 |

235 |

227 |

183.5 |

|||||||||

|

125 |

16 |

125 |

325 |

183 |

18.0 x 8 |

210 |

250 |

260 |

211 |

27 |

1-3/8''-12UNF |

28 |

600 |

F12 |

51 |

|

40 |

26.0 x 8 |

220 |

270 |

||||||||||||

|

150 |

16 |

150 |

350 |

204 |

22.0 x 8 |

240 |

285 |

280 |

232 |

27 |

1-3/8''-12UNF |

28 |

800 |

F12 |

72.5 |

|

40 |

26.0 x 8 |

250 |

300 |

||||||||||||

|

200 |

16 |

200 |

400 |

252 |

22.0 x 12 |

295 |

340 |

450 |

280 |

27 |

1-3/4''-12UNF |

28 |

800 |

F12 |

144.3 |

|

40 |

30.0 x 12 |

320 |

375 |

Note: All the data should be confirmed with the approved drawings of manufacturer.

RST VALVE is looking forward to strengthening cooperation with various sectors of society to create brilliancy together.

MADE IN CHINA, FOCUS ON WORLD!

Tel: 0086 576 87449065

Fax: 0086 576 87467338

Mob/whatsapp: 0086 13736571023

E-mail: info@reachvalve.com